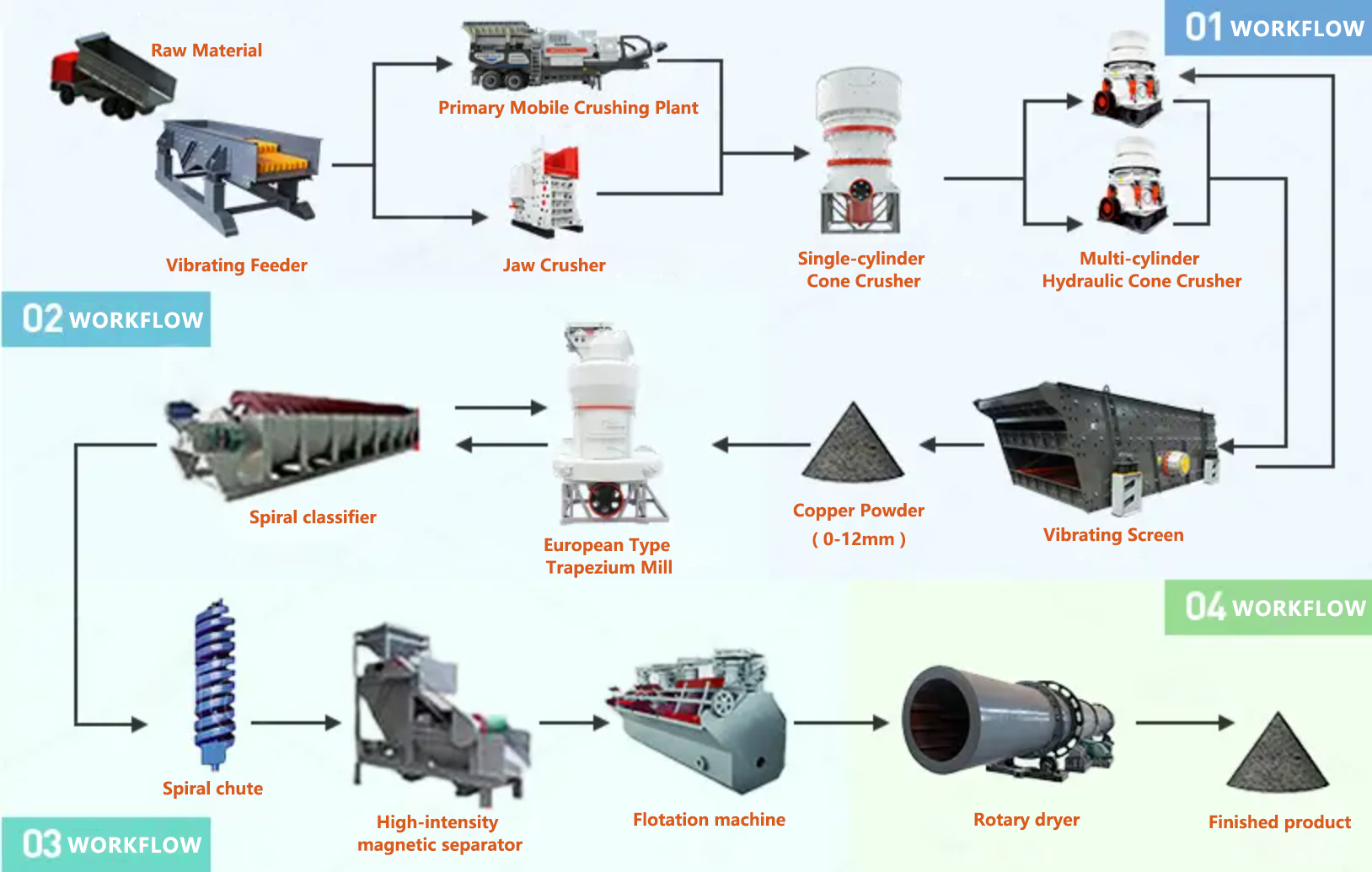

Copper ore processing primarily involves three steps: crushing, grinding, and beneficiation. Three-stage closed-circuit crushing is a modern method suitable for crushing high-hardness copper ores. It can achieve both ore crushing and partial dissociation, thereby improving subsequent grinding efficiency. Two-stage, one-closed-circuit grinding allows for more complete grinding of the copper ore. Among beneficiation processes, the most successful new technology that has emerged in recent years is hybrid flotation.

Stage 1: Crushing and Screening – Three-Stage Closed-Circuit Crushing

Large copper ore is evenly fed from a hopper via a vibrating feeder into a jaw crusher or mobile crushing station (primary crushing) for primary crushing. The coarsely crushed copper ore is screened on a vibrating screen and then conveyed by a belt conveyor to a single-cylinder hydraulic cone crusher (secondary crushing) for secondary crushing. The secondary crushed copper ore is then fed into a multi-cylinder hydraulic cone crusher for fine crushing.

Stage 2: Grinding – Two-Stage, One-Closed-Circuit Grinding

Copper powder (0-12 mm) sized after vibrating screen screening is evenly fed into a grinding mill for grinding. It is then screened by a spiral classifier, and those that do not meet the requirements are fed into a grinding mill for further grinding.

Stage 3: Ore Beneficiation – Taking Flotation as an Example

Steps: The ore pulp after grinding and classification is fed into a flotation cell for flotation. During the flotation process, the type, dosage, and operating conditions of the flotation reagents must be appropriately adjusted to obtain a high-grade copper concentrate.

Equipment: Flotation cell, flotation column, etc.

Stage 4: Concentrate Dewatering and Tailings Treatment

Through concentration, filtration, and drying, moisture is removed from the concentrate to facilitate subsequent smelting and processing. Concentration is performed in a concentrator, filtration is typically performed on a filter, and drying is accomplished in a dryer.

Tailors storage is a common method of tailings disposal, while tailings re-selection and comprehensive tailings utilization help improve resource utilization and reduce environmental pollution.

Due to the wide variety of copper ores and different ore characteristics, the configuration of the production line will also be different. For specific configurations, please contact Shengbang Machinery WhatsApp +8613949025317 to arrange according to your actual situation.

Fill in the information and we will contact you as soon as possible